Need Custom Packaging Boxes?

Get Free Quote

We’re more than happy to assist in your packaging project.

Green Philosophy

We go eco-friendly in day to day operation to bring positive

impact on your brand, as well as our environment.

Reduced Carbon Emission

Most direct emissions produced by packaging factories during production come from carbon footprint in manufacturing consuming fossil fuels for energy.

StarSeed operates as many printing processes as possible in-house, which reduces carbon emission attributed to frequent transportation. We pay attention to maintaining our machines and revamping our facilities on a regular basis and elevating them to a more energy-efficient level.

Waste Gas Disposal

StarSeed adopts measures that contribute to overall sustainability and reduce contributions to global warming and climate change. By doing so we’re helping to ensure a safe, healthy environment not only now, but for generations to come.

The waste gas generated in the process of manufacturing is collected and treated by the waste disposal system. The gas being adsorbed by the activated carbon will then be released to a height above 15 meters, which is fully in line with national regulations to keep a sustainable air standard.

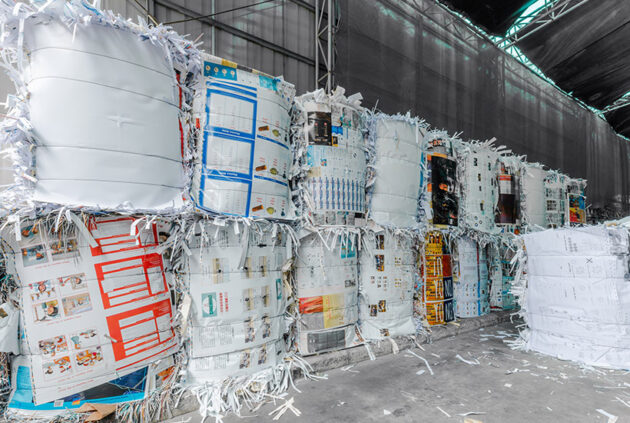

Cardboard Recycle

Packaging factories produce scrap paper no matter how accurately they make the die cut. With the “Reduce, Reuse, Recycle” principle in mind, StarSeed has made waste cardboard recycle even more effective.

We collect scrap paper boards generated in our manufacturing process every day, and set an area for keeping them. By the end of our shift, all waste paper boards would be sent to recycling companies where paper board are smashed and converted into a laminated plate of the corrugated board so that they can be reused to produce cardboard.