Brand Story

Class A is a long-established Australian jewelry brand that was founded on Valentine’s Day 1972 and has been in business for 49 years. It has 3 sub-brands including Petite, Link for Life and Class A collection. Class A also has its own handcrafted jewelry workshop that helps to customize unique rings, bracelets, earrings, pendants and necklaces for customers.

All-in-One Packaging Solution

The Client’s Needs

Responding to the increasing market demand, Class A has been seeking a way forward out of its limited offline sales channel. Online sales turned out to be a good choice for Class A. As their online business grew, Class A started to look for a box that better met their shipping packaging requirements

They finally decided to use the mailer box which is convenient for transportation. As the mailer box makes the first impression while the consumers receive the product, it’s of great importance to enhance the feeling of the product. Compared with the ordinary carton, the advantages of mailer boxes are clear:

- Eco-friendly ear lock mechanism that requires no tape while using

- Easy-to-use after folding and saves space while transporting from the factory

- Beautifully printed words and logos

- Made of corrugated paper with strong structure to resist pressure and fall, providing extra protection for goods.

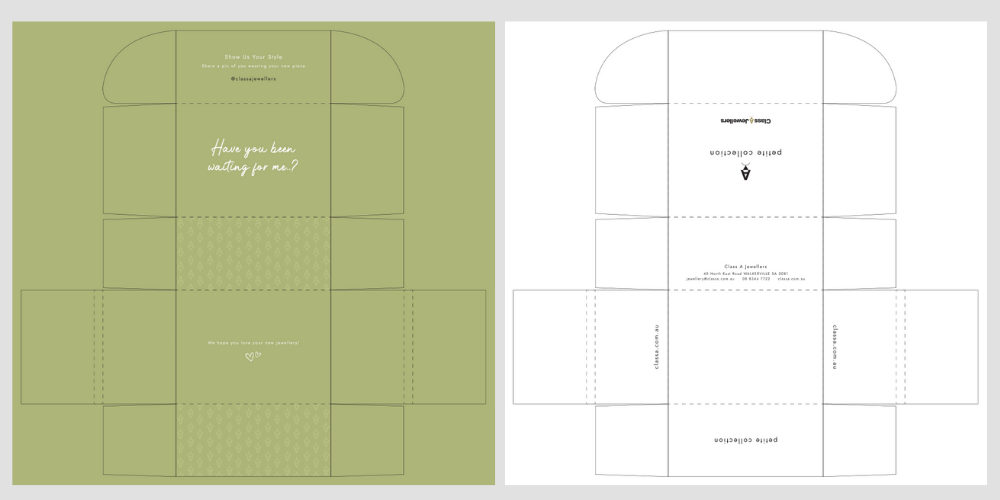

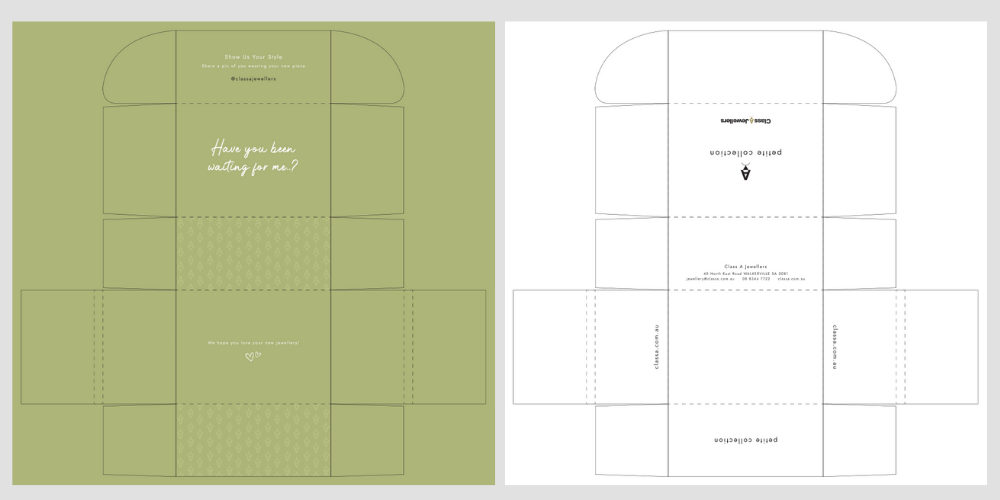

Packaging Design for Petite

The mailer box designed for Petite adopted double-sided printing. The outer side is designed with a simple white-and-black logo, along with the store’s address, website, and contact information.

On the reverse side of the box there is a printed slogan. So the customers can see the words “Have you been waiting for me” immediately when they open the box.

At the bottom of the box we can see another words “We hope you love your new jewelry! A vaguely visible logo inside the box is printed to enhance the brand image.

The hardness of the mailer box is very important for protecting the product. After multiple researches and tests, StarSeed Packaging team decided to use 3-layer E-Flute corrugated cardboard. With 250g double copper paper laminated on both sides, the overall thickness of the cardboard reached 2.5mm. In addition, both sides are laminated with matte, giving the mailer box a perfect texture and touch feel.

Printing and Manufacturing

For brands who are seeking quality printing, color difference is the top 1 problem that haunts them. Because the spot color printing is too costly for smaller orders, and brand owners are just too far away from the manufacturers to have any on-site monitoring over the printing process.

In order to support the massive amount of starting up businesses and complete small-volume trial orders, StarSeed Packaging has purchased 4 Fuji digital printing presses imported from Japan this year, which cost much higher than an ordinary four-color printing presses per unit.

The digital press does not require any platemaking step, which greatly saves money and time for preparation. This allows StarSeed Packaging to accept smaller orders starting from 100 PCS.

There has always been a major difference between digital printing and offset printing in terms of vividness of color. However, the finished effect and color done by Fuji digital printing amazingly achieves international color management under G7 Certification, comparable to that of industrial offset printing.

The color is controlled and automatically adjusted by computer in line with the design throughout the entire process without any color correction job by manual, allowing brands to print remotely without worrying about color differences even when they are overseas.

Besides, the machine supports automatic UV spot while printing. the whole process of machine control, precise operation, saving manpower and material resources.

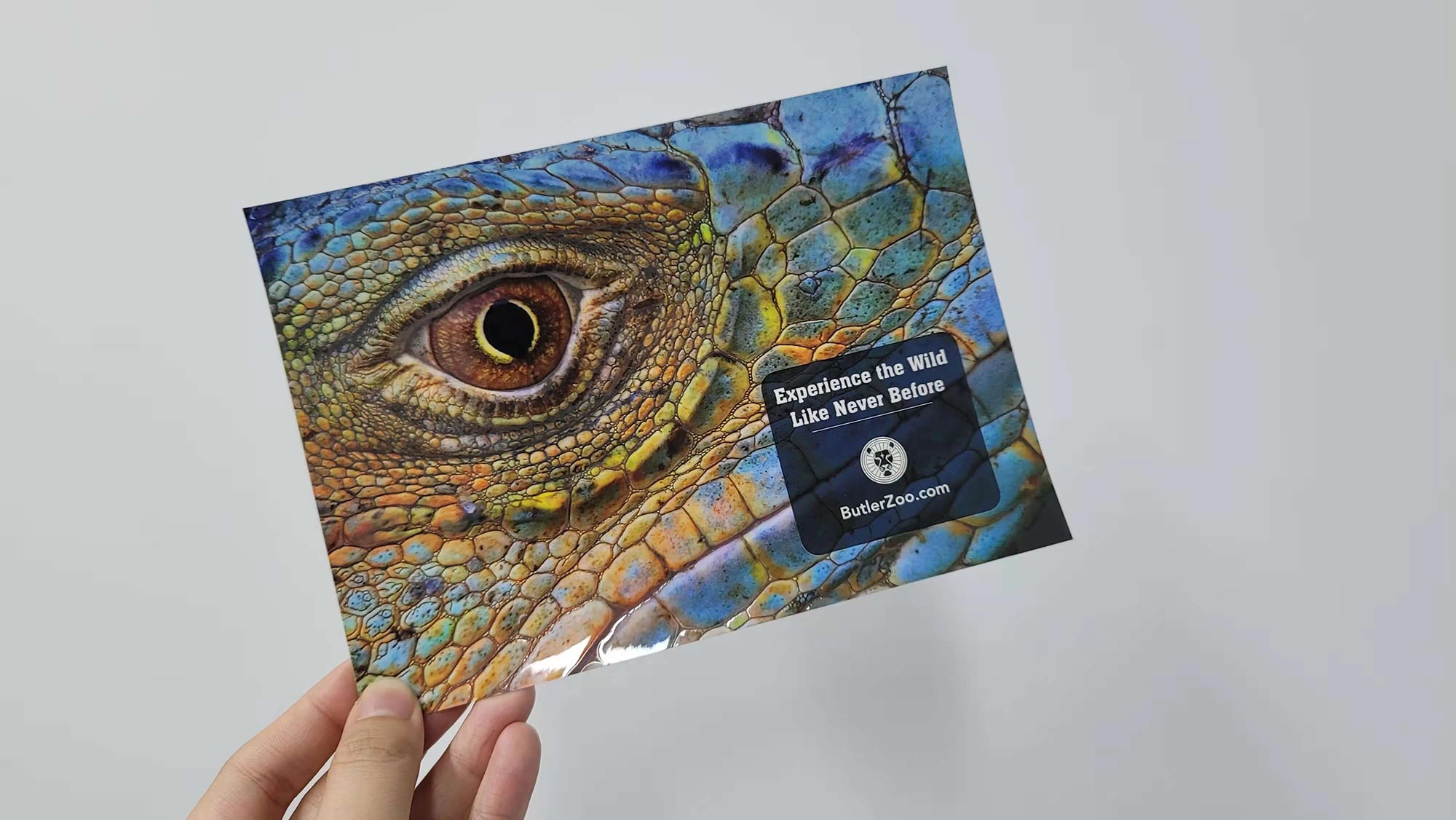

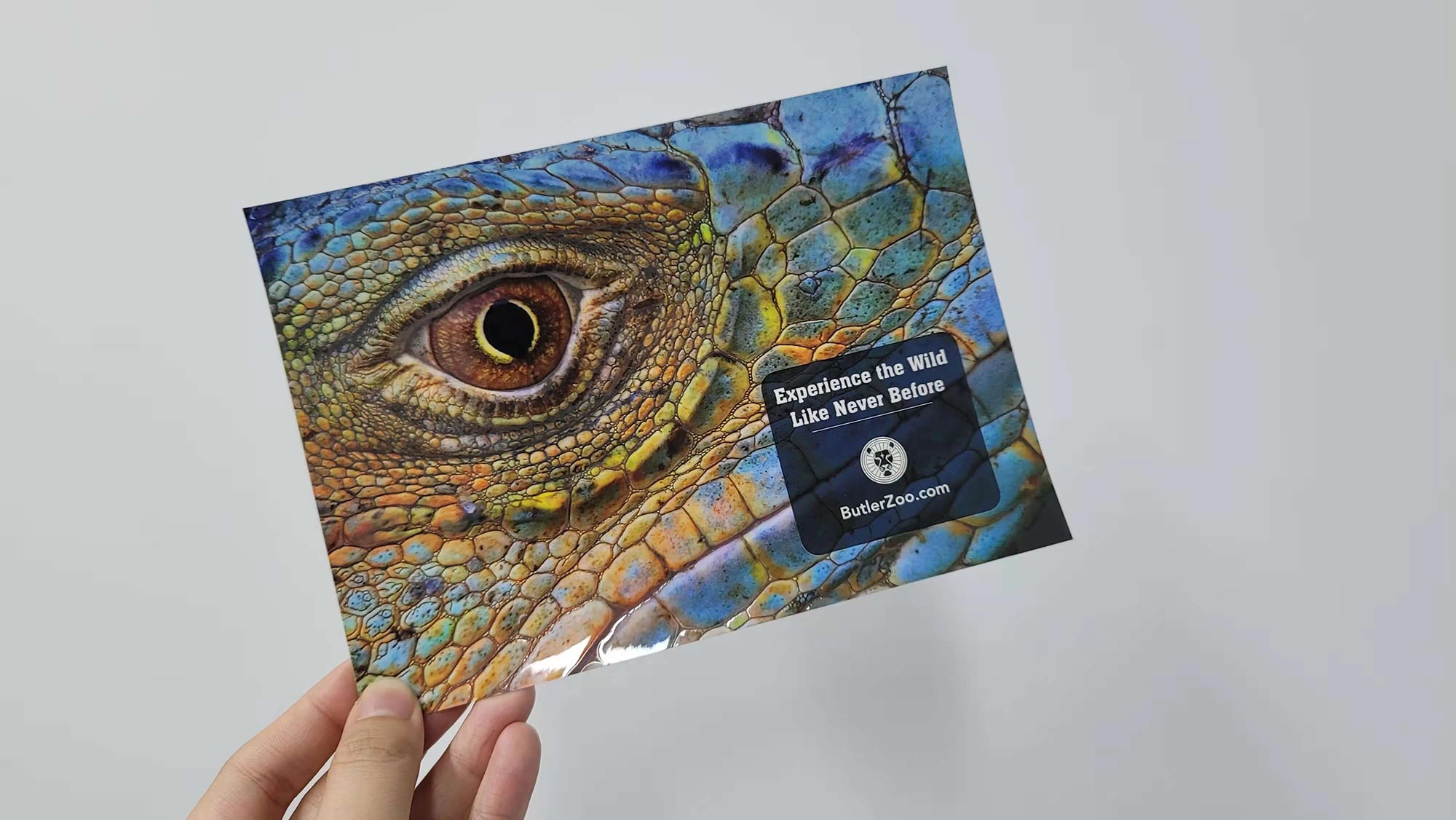

(G7 certified Fuji digital press printed material – digital printing with UV spot )

(G7 certified Fuji digital press printed material – digital printing with UV spot )

Only True Feedback Counts

The customer is very satisfied after receiving the product and is looking forward to the follow-up cooperation.

(G7 certified Fuji digital press printed material – digital printing with UV spot )

(G7 certified Fuji digital press printed material – digital printing with UV spot )